John Crane’s USP seal design to improve pump efficiency, sustainability

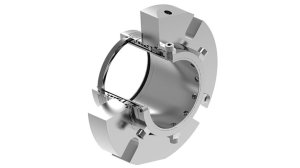

IDEAL DESIGN The non-contacting design of John Crane’s USP mechanical seals helps to reduce friction, prevent wear and extend pump life in abrasive and corrosive environments

USP SPIRAL GROOVE This technology combines spiral groove features with a dual cartridge system for enhanced durability and performance

USP TYPE SB2A The USP mechanical seal from John Crane performs even in harsh environments where conventional seals fail

Using spiral groove technology, the Upstream Pumping (USP) mechanical seals from Gauteng-based John Crane are designed to provide reliable, high-pressure seals for pump systems operating in challenging mining, minerals processing and refining applications.

The non-contacting design helps to reduce friction, prevent wear and extend pump life, making it ideal for abrasive slurries and corrosive substances, the company explains.

The John Crane Type SB2USP seal exemplifies this technology, combining spiral groove features with a dual cartridge system for enhanced durability and performance, even in harsh environments where conventional seals fail.

Other benefits associated with these seals include reduced cooling water requirements, water use and improved reliability and energy efficiency, says John Crane.

USP seals’ near-frictionless operation generates negligible heat, reducing or eliminating the need for cooling systems, making them a sustainable choice for water-conscious operators. This is in addition to being ideal for remote, water-scarce locations, with the USP seal operating with minimal barrier fluid.

Flush water use is also drastically reduced, consuming a few millilitres of water an hour, compared with conventional seals that require up to 8 ℓ/min. In addition, unlike traditional seals, which typically require repairs every two to three years, USP seals often run for five years or more, with some lasting more than a decade in demanding environments, claims John Crane.

The company says this results in longer intervals between repairs, lower maintenance costs and enhanced operational uptime.

Its low-friction design also decreases motor torque, lowering energy consumption, and supports decarbonisation goals.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation